Transforming Plastics

Circularity

Through our Polymer Center network, Republic Services is transforming the plastics value chain, from curbside collection to consumer packaging and back again. Our Polymer Centers are helping ensure a plastic bottle or jug is turned back into a new bottle or jug, advancing plastics circularity.

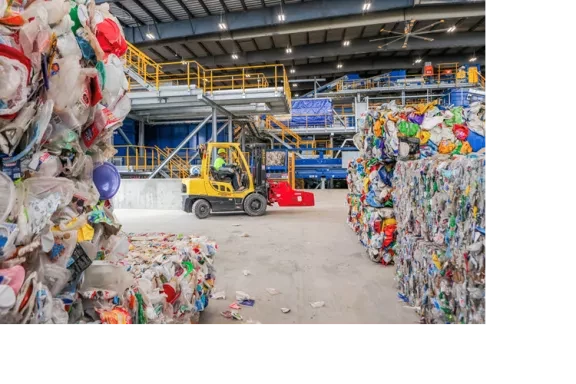

Reimagining recycling

The Republic Services Polymer Centers are the first recycling facilities of their kind in North America, processing plastics collected from homes and businesses and producing specialized recycled resins ready for use in sustainable packaging.

Challenge

Traditionally, many plastics have been downcycled into products that have few options for further recycling – like clothing, carpet or construction pipe.

Solution

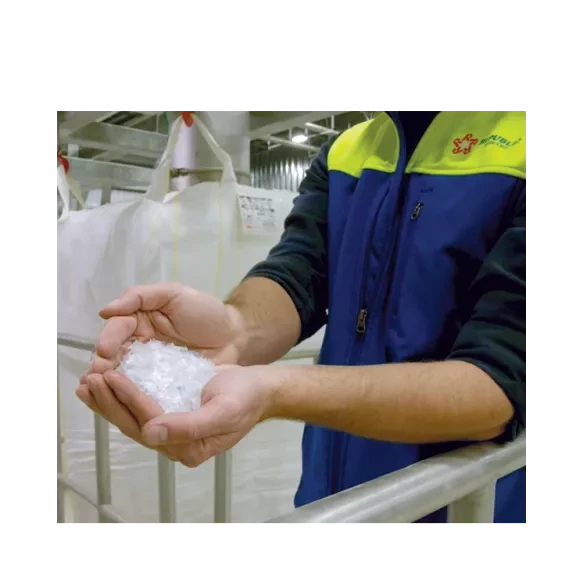

Our Polymer Centers produce high-quality, color-sorted recycled PET, HDPE and Polypropylene (PP), ready for use in sustainable packaging to meet voluntary commitments and legislative mandates.

Circular Solutions from the Polymer Center

Our Polymer Centers’ innovative secondary-sorting process is designed to enable true packaging circularity.

PET (water or soda bottles) is diverted to one path, which includes AI-powered optical scanning, shredding into flakes and cleaning. The result is a clear, hot-washed rPET flake ready to be remanufactured into a beverage bottle.

HDPE (milk or detergent jugs) and PP (yogurt cups, margarine tubs) follow a second path, which includes a series of optical and medium-infrared scanners. These specially sorted plastics are baled by color and type.

Bales of color-sorted HDPE and PP then go to a

As one of the nation's largest recyclers, Republic Services is uniquely positioned to support the circular economy. The Polymer Center is an important step toward our 2030 goal of increasing the recovery and circularity of valuable materials by 40%. With our investment in leading technologies like these, we're also helping manufacturers meet their sustainability goals and the expectations of today's consumers.